What Are Seamless Tubes Used for in 2024?

Seamless tubes continue to play a vital role in various industries, thanks to their strength, durability, and ability to withstand extreme conditions. In 2024, these tubes find applications in several key sectors where their unique properties offer significant advantages.

Oil and Gas Industry

Seamless tubes are essential in the oil and gas industry, where they are used for drilling, transporting, and refining hydrocarbons. Their ability to withstand high pressure and corrosive environments makes them ideal for use in pipelines, well casings, and refineries. In 2024, with the global focus on energy security and efficiency, these tubes are more crucial than ever in maintaining the integrity of these critical systems.

Automotive Manufacturing

The automotive industry relies on seamless tubes for various applications, including fuel injection systems, hydraulic cylinders, and structural components. As the industry continues to innovate in 2024, particularly with the rise of electric vehicles (EVs), the demand for high-quality, durable materials like these tubes is increasing. These tubes contribute to the light-weighting of vehicles, improving fuel efficiency and reducing emissions.

Aerospace and Aviation

In aerospace, seamless tubes are used in aircraft hydraulic systems, fuel lines, and structural components. Their strength allows them to withstand extreme temperatures and pressures. This makes them indispensable for ensuring the safety and efficiency of modern aircraft. As the aerospace industry pushes the boundaries of innovation in 2024, these tubes play a critical role. They are essential in developing next-generation aircraft and space exploration vehicles.

Power Generation

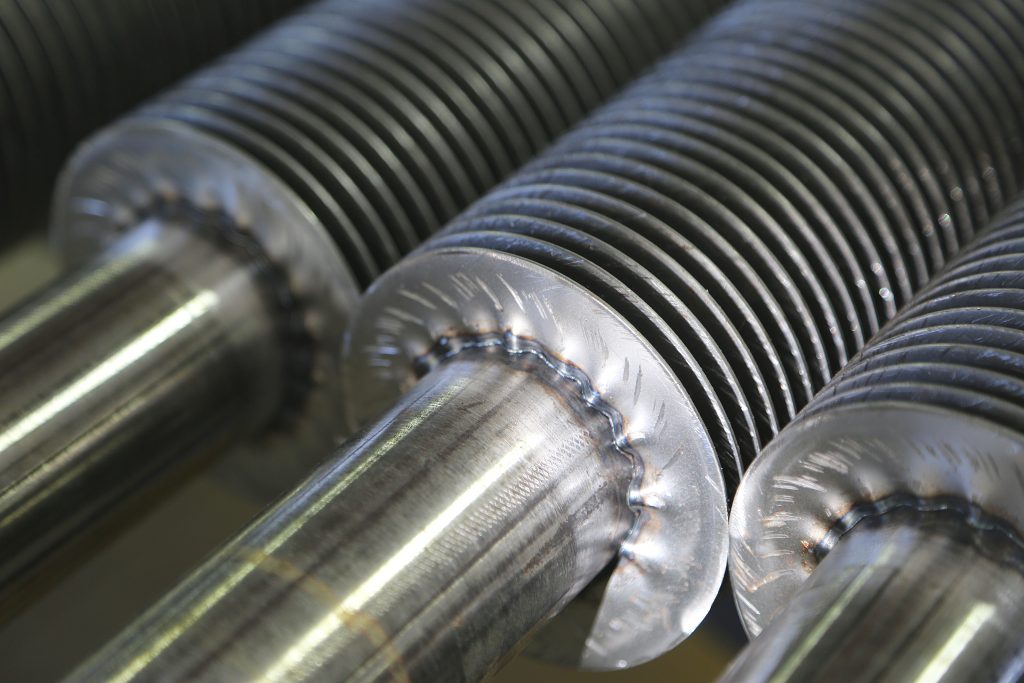

Power plants, particularly those that rely on fossil fuels or nuclear energy, use seamless tubes in their boilers, heat exchangers, and condensers. These tubes must endure high temperatures and pressures while maintaining excellent corrosion resistance. In 2024, with the global push towards more efficient and sustainable energy production, seamless tubes play a significant role in ensuring the reliability and efficiency of power generation systems.

Construction and Infrastructure

Seamless tubes are widely used in the construction industry for structural applications, including bridges, buildings, and industrial structures. Their high strength and durability make them suitable for critical infrastructure projects that demand long-term reliability.

Medical Industry

The medical industry uses these tubes in the manufacturing of surgical instruments, medical devices, and implants. The precision and high quality required for these applications make seamless tubes an excellent choice. In 2024, as medical technology advances, the demand for these tubes that meet stringent safety and performance standards continues to grow.

Conclusion

In 2024, seamless tubes remain integral to a wide range of industries, from oil and gas to aerospace, automotive manufacturing, power generation, construction, and healthcare. Their ability to provide superior performance under extreme conditions ensures their continued relevance and demand across these critical sectors. As industries evolve and innovate, these tubes will undoubtedly continue to play a key role in meeting the challenges of the modern world.